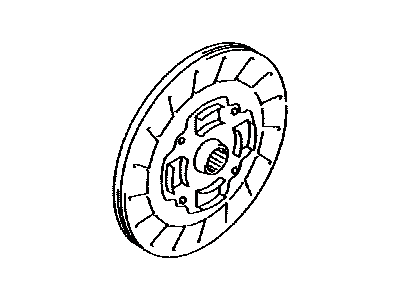

Access to the clutch components is accomplished by removing the transaxle and engine assembly as a unit. Separate the transaxle from the engine, allowing the release fork (for 2009 and earlier models) and release bearing to remain attached to the transaxle temporarily. To support the clutch disc during removal, install a clutch alignment tool through the clutch disc hub. Carefully inspect the flywheel and pressure plate for indexing marks, which are usually an X, an O, or a white letter; if they cannot be found, scribe marks yourself to ensure proper alignment during installation. Slowly loosen the pressure plate-to-flywheel bolts in a diagonal pattern, relieving spring pressure before completely removing the bolts, followed by the pressure plate and clutch disc. When a problem occurs in the clutch, it is typically due to wear of the clutch driven plate assembly, but all components should be inspected. Check the flywheel for cracks, heat checking, score marks, and other damage; slight imperfections can be resurfaced. Inspect the lining on the clutch disc, ensuring at least 1/16-inch of lining above the rivet heads, and look for loose rivets, distortion, cracks, and broken springs. The release bearing should be replaced along with the clutch disc. Examine the pressure plate's machined surface and diaphragm spring fingers for score marks, cracks, and signs of overheating; replace the pressure plate assembly if damaged. Before installation, wipe the flywheel and pressure plate machined surfaces clean, ensuring no oil or grease is present. Position the clutch disc and pressure plate with the clutch held in place using an alignment tool, ensuring proper installation. Tighten the pressure plate-to-flywheel bolts only finger-tight, working around the pressure plate. Center the clutch disc by ensuring the alignment tool is through the splined hub and into the crankshaft recess, then tighten the bolts in a crisscross pattern to prevent distortion, finishing by tightening them to the specified torque and removing the alignment tool. Lubricate the inner groove of the release bearing with high-temperature grease, applying grease to the release lever contact areas and the transaxle input-shaft bearing retainer before installing the clutch release bearing. Finally, reinstall the transaxle and all previously removed components, tightening all fasteners to the proper torque specifications.

Posted by ToyotaPartsDeal Specialist