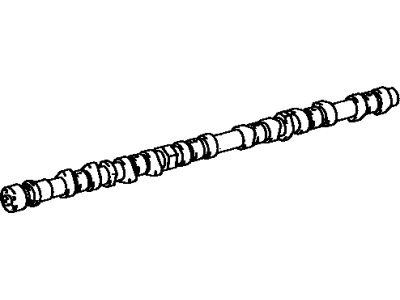

To remove the components mentioned above one has to begin with the disconnection of the cable from the negative terminal of the battery. Next, unclip the brackets for the accelerator cable and TV cable from the valve covers, then in the event that the motor is operating, set the number one piston at TDC on the compression stroke and take out the distributor or the camshaft position sensor. I. Again, depending on the model, for non-turbo models, the No. 1 air cleaner hose plus the intake connector pipe should be detached; while for turbo models, both the No. 4 air cleaner pipe and both the No. 1 and No. 2 air cleaner hoses should be detached. Cover and promptly disconnect all the coolant, fuel, vacuum transmission and electric wiring harnesses and hoses that they must label the connectors and coil the harnesses and keep them aside. Depower the valve cover, heater hose, and then by using a proper tool, take off the No. 3 cylinder head cover. I then locate and take off the spark plugs, crankshaft pulley, timing belt cover, and the timing belt and No. 2 timing belt cover as well. Turn each bearing cap bolt, in the mentioned sequence until they can be removed, followed by the removal of the camshaft bearing caps, the oil seals and the camshafts while retaining the bearing caps in order. Next, you should pull out the shims and the valve lifters where you spent most of your time; therefore, take time and arrange them in the correct order to avoid confusion. Visually check the camshaft, shims, and valve lifters for excessive wear, or scoring also check the diameter of each valve lifter and the lifter bores and compare with the clearances. Check the runout of the circle of the center journal of each camshaft and the cam lobe height, then replace any of the ones that are not correct. Scrub the camshaft bearing caps and journals, install the camshafts into the respective head, and run a Plastigage at each cam journal to check the clearance, and wherever needed, overhaul the component. Remove all the material off the Plastigage and fit the camshaft along with the bearing caps, and then conclude by checking the end play of camshaft. If installing new valve guide seals are to be done then it can only be effected with cylinder head still on the block. During erection, degrease both camshafts, Shims, and Lifter, apply engine oil and new gaskets and seals. Next, fit the valves, springs, retainers, and keepers; then the lifters, with shims, provided all the shims are returned to their respective bores. Drench the new camshaft oil seals with clean engine oil or grease and fit them, coat all the bearing journals with fresh oil and fit the camshaft in the cylinder head. Spread RTV sealant on the mentioned locations, orient the bearing caps based on numbers and arrows pointing forward, and tighten the bveld-cap screws in sequences. Squirt a little grease into the holes and drive the camshaft seals into place with a suitable tool-do not cock the seal. Then slightly increase the torque of the No 3 and No 7 bearing cap bolts and continue with the other bearing cap bolts and then measure the total camshaft end play again. Last of all, perform all the actions in the opposite order as to which they were removed, if there were any previous steps.

Posted by ToyotaPartsDeal Specialist