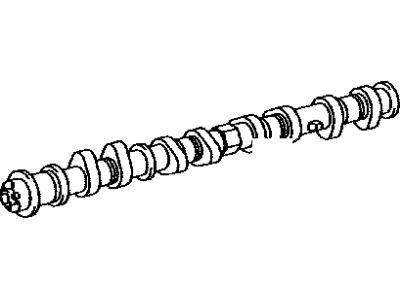

Get the reliability of purchasing Toyota part # 13501-66020 Camshaft. It is also referred to as Camshaft. The first option should always be to use OEM parts. Toyota manufactures these components with high quality material and rigorously tested with high reliability and durability. This part fits 1992-1997 Land Cruiser.

ToyotaPartsDeal.com is a leading supplier of genuine Toyota parts and accessories, such as 1350166020 Camshaft. In need of OEM Toyota parts? We offer a wide selection of genuine parts available that are competitively priced and trusted across the market. All parts are warranted by the manufacturer. Combine that with our simple return policy and fast delivery service and your shopping experience will be stress-free and dependable. For detailed Toyota parts information, click here.