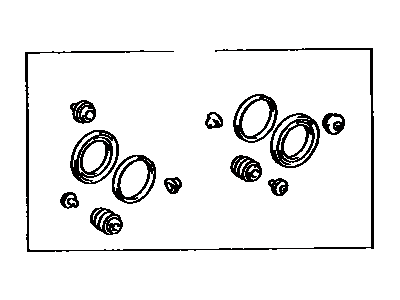

Before the overhaul is carried out, which is typical for such a situation due to leakage or sticky motion, review all of the viable solutions. New wheel cylinders are available, and as a result, replacing them is among the easiest tasks. If the above option of rebuilding the wheel cylinder is selected, then it is advised to make sure that a rebuild kit is accessible. Never just overhaul or change only one wheel cylinder on a car, always do both at the same time. Before beginning the removal, lift the front or rear of the vehicle off the ground and secure it on jackstands, and turning the nonworking type of wheels and preventing them to roll around. Completely withdraw the brake shoe assembly, you should also clean all the dirt as well as other material that may be within or around the wheel cylinder. Use a flare-nut wrench if available, to unscrew the brake line(s) and then undo the wheel cylinder mounting bolts. Remove the wheel cylinder from the brake backing plate and put it on a flat surface, there is always need to cap off the brake line to avoid running off or spoiling of the brake fluid. In preparing the setback, take away the bleeder screw, boots, pistons, cups, and spring from the wheel cylinder housing. Using brake fluid, denaturealised alcohol or brake system cleaner, clean the wheel cylinder but avoid using petroleum solvent. After removing the rubber boot, it is advisable to use compressed air to completely dry the wheel cylinder AND blow out the passages. Examine bore for rust and scratches; if the rust is not severe, it can be rubbed out with crocus; but if the defects cannot be rubbed out or if the bore is scratched, get a new cylinder. Clean the new cups by wiping them with brake fluid and fitting the brake cylinder parts with cup lips facing the center. For installation, position the wheel cylinder of the brake of the vehicle in the correct manner before fastening the bolts loosely on the cylinder and this should be particularly done on vehicles with dual leading type of brake. Join the brake line(s) to the cylinder without overtightening the threads on the fittings, then torque the wheel cylinder bolts to the manufacturer's recommended value. After that, the brake line(s) should be securely tightened, and the brake shoe assembly should be put to its place. Last but not least, release pressure in the brake system and examine the brake system's functionality before operating the automobile cautiously.

Posted by ToyotaPartsDeal Specialist