×

- Live Chat

- 1-888-905-9199

My Garage

My Account

Cart

Genuine Toyota 4Runner CV Joint

CV Joint Axle- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 CV Joints found

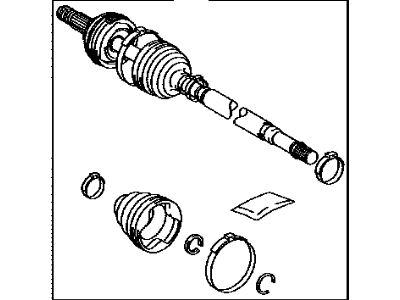

Toyota 4Runner Shaft Assembly Front Drive Outboard Joint Right

Part Number: 43460-69105$214.94 MSRP: $308.20You Save: $93.26 (31%)Toyota 4Runner Shaft Assembly, Front Drive Outboard Joint, Right

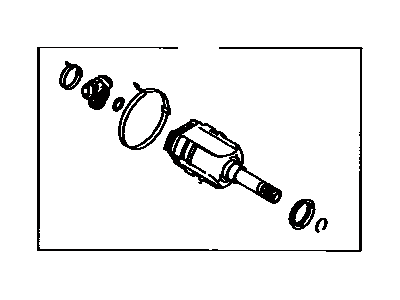

Part Number: 43460-39065$186.35 MSRP: $267.22You Save: $80.87 (31%)Ships in 1-3 Business DaysToyota 4Runner Joint Assembly, Front Axle Inboard

Part Number: 43403-35030$340.30 MSRP: $487.96You Save: $147.66 (31%)Ships in 1-3 Business DaysToyota 4Runner Shaft Assembly, Front Drive Outboard Joint, Left

Part Number: 43460-69055$214.94 MSRP: $308.20You Save: $93.26 (31%)Ships in 1-3 Business DaysToyota 4Runner Shaft Assembly Front Drive Outboard Joint Right

Part Number: 43460-39026$259.50 MSRP: $372.11You Save: $112.61 (31%)Ships in 1-3 Business DaysToyota 4Runner Shaft Assembly, Front Drive Outboard Joint, Right

Part Number: 43460-39025$259.50 MSRP: $372.11You Save: $112.61 (31%)Ships in 1-3 Business DaysToyota 4Runner Shaft Assembly, Front Drive Outboard Joint, Left

Part Number: 43460-39027$259.50 MSRP: $372.11You Save: $112.61 (31%)Ships in 1-3 Business DaysToyota 4Runner Joint Assembly, Front Axle Inboard, Left

Part Number: 43403-39035$433.04 MSRP: $637.43You Save: $204.39 (33%)Ships in 1-3 Business DaysToyota 4Runner Shaft Assembly Front Drive Outboard Joint Right

Part Number: 43460-39045$251.38 MSRP: $360.46You Save: $109.08 (31%)Ships in 1-3 Business DaysToyota 4Runner Shaft Assembly, Front Drive Outboard Joint, Left

Part Number: 43460-39046$251.38 MSRP: $360.46You Save: $109.08 (31%)Ships in 1-3 Business DaysToyota 4Runner Joint Assembly, Front Axle Inboard

Part Number: 43403-60020$543.53 MSRP: $800.08You Save: $256.55 (33%)Toyota 4Runner Joint Assembly, Front Axle Inboard, Right

Part Number: 43403-35020$433.04 MSRP: $637.43You Save: $204.39 (33%)

Toyota 4Runner CV Joint

If you are in demand for superior quality and affordable OEM Toyota 4Runner CV Joint, then shop with us! We own a wide range of the reduced-priced genuine Toyota 4Runner CV Joint. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

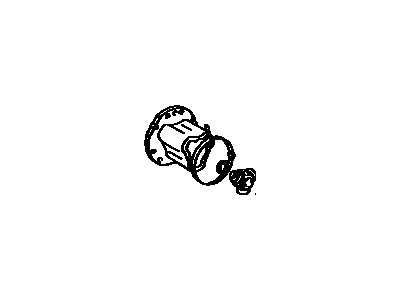

Toyota 4Runner CV Joint Parts Questions & Experts Answers

- Q: What are the steps and considerations for overhauling CV joints and boots on 1996 through 2002 Toyota 4Runner?A: If the CV joints have to be replaced, one should consider all viable possibilities before starting the task, as rebuilt CV boot sets are available on an exchange basis, which will prove beneficial in the long run. In either case, compare the cost and whereabouts of the respective spares before dismantling the car, and do not dismantle the outboard CV joint. Mount the CV boot in a vice with the wood-lined jaws and this is to avoid damaging the axle in the process for it will be easy to check if the CV joint is moving excessively to and from that is flexible of smooth operation when subjected to force. If a particular boot is damaged it should be dissembled by unzipping the joint area where the fabric is ripped and then the parts should be cleaned to check for further damages. With a small screwdriver, you should pull the retaining tabs of the clamps; To do it, pry up the outer boot of your hard drive and take it off. Draw the inner CV joint boot back and remove the housing from the tripod while noting the position of the tripod and the axleshaft for proper assembly. The snap-ring which secures the tripod joint is to be taken out by snap-ring pliers, now use a hammer and a brass punch tool while applying care not to harm the bearing surfaces of the tripod joint to be dismounted from the CV boot. If not already done, remove both boots and apply protection to the splines at the internal end of the axleshaft using some type of tape. Remove all the components which are soaked in solvent to check the surfaces of bearings for wearing; in case of wear on the inner CV joint, the new joint can be put on the old axleshaft, but in the case of wear on the outer joint, the new outer joint and the axleshaft are needed. To break down, first you have to slide off the clamps and the boot over the axleshaft; next place the tripod over the shaft; apply grease and then the tripod into its housing and pack grease around it. Adjust the position of the boot, center the driveshaft stump on the axle, pump the boot to the same pressure, put the boot band into position before securing the driveshaft and the new assembly.

Related Toyota 4Runner Parts

Browse by Year

2009 CV Joint 2008 CV Joint 2007 CV Joint 2006 CV Joint 2005 CV Joint 2004 CV Joint 2003 CV Joint 2002 CV Joint 2001 CV Joint 2000 CV Joint 1999 CV Joint 1998 CV Joint 1997 CV Joint 1996 CV Joint 1995 CV Joint 1994 CV Joint 1993 CV Joint 1992 CV Joint 1991 CV Joint 1990 CV Joint 1989 CV Joint 1988 CV Joint 1987 CV Joint 1986 CV Joint 1985 CV Joint