My Garage

My Account

Cart

Genuine Toyota Camry Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

43 Oil Pans found

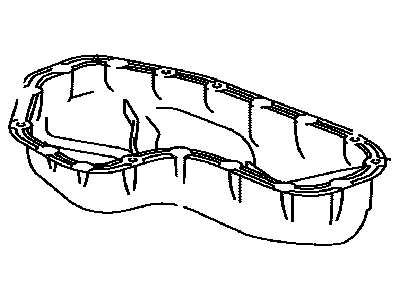

Toyota Camry Oil Pan Sub-Assembly

Part Number: 12102-0P020$141.44 MSRP: $201.08You Save: $59.64 (30%)Ships in 1-2 Business DaysToyota Camry Pan Sub-Assembly, Oil, N

Part Number: 12102-0P041$145.30 MSRP: $206.58You Save: $61.28 (30%)Ships in 1-2 Business DaysToyota Camry Oil Pan Sub-Assembly

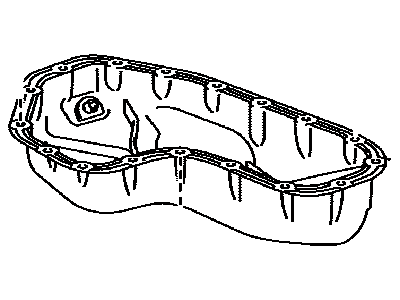

Part Number: 12101-0V010$119.56 MSRP: $169.98You Save: $50.42 (30%)Ships in 1 Business DayToyota Camry Oil Pan Sub-Assembly

Part Number: 12102-20010$173.62 MSRP: $246.83You Save: $73.21 (30%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

Part Number: 12102-0A010$173.62 MSRP: $246.83You Save: $73.21 (30%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

Part Number: 12101-28060$126.23 MSRP: $179.45You Save: $53.22 (30%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

Part Number: 12101-0H010$123.42 MSRP: $175.47You Save: $52.05 (30%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

Part Number: 12101-0P040$187.21 MSRP: $268.45You Save: $81.24 (31%)Ships in 1-2 Business DaysToyota Camry Pan Sub-Assembly, Oil, N

Part Number: 12102-F0010$114.09 MSRP: $160.83You Save: $46.74 (30%)Ships in 1-3 Business DaysToyota Camry Pan Sub-Assembly, Oil, N

Part Number: 12102-25010$114.09 MSRP: $160.83You Save: $46.74 (30%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

Part Number: 12101-0H050$126.23 MSRP: $179.45You Save: $53.22 (30%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

Part Number: 12101-28030$123.42 MSRP: $175.47You Save: $52.05 (30%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

Part Number: 12102-31050$141.44 MSRP: $201.08You Save: $59.64 (30%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

Part Number: 12101-31121$187.21 MSRP: $268.45You Save: $81.24 (31%)Ships in 1-3 Business DaysToyota Camry Pan Sub-Assembly, Oil, N

Part Number: 12102-31051$141.44 MSRP: $201.08You Save: $59.64 (30%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

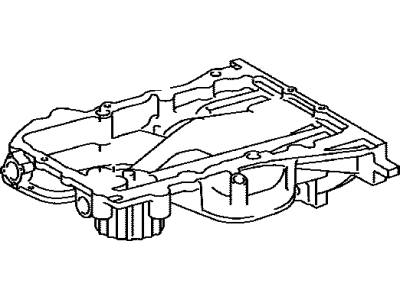

Part Number: 12111-0A040$229.67 MSRP: $329.33You Save: $99.66 (31%)Ships in 1-3 Business DaysToyota Camry Oil Pan Sub-Assembly

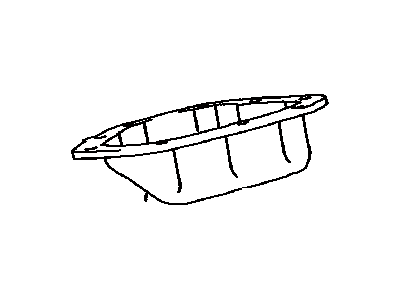

Part Number: 12101-36040$119.56 MSRP: $169.98You Save: $50.42 (30%)Ships in 1-3 Business DaysToyota Camry Pan, Oil, NO.1

Part Number: 12111-0P070$186.28 MSRP: $267.11You Save: $80.83 (31%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 43 Results

Toyota Camry Oil Pan

Toyota Camry Oil Pan is an important part that holds the engine oil which is required to lubricate the vehicles' engine correctly. Located just below the engine, oil pan is a receptacle or sump which holds the oil to get circulated and lubricate the different parts of the engine. Considering that the purpose of an oil pan is to collect any dripping oil and to maintain a consistent levels of oil, the oil pan has to be undamaged. The standard oil pans are typical motor vehicle structures but racing motorcycles and piston aircraft engines have a 'dry sump' system in tackling issues like oil starvation during cornering among others. If you find that your car has developed oil stains somewhere close to the engine, especially round the Toyota Camry, it will be advisable to change the oil pan so that no more extra and unwanted problems of oil leakage are experienced.

If you are in demand for superior quality and affordable OEM Toyota Camry Oil Pan, then shop with us! We own a wide range of the reduced-priced genuine Toyota Camry Oil Pan. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Camry Oil Pan Parts Questions & Experts Answers

- Q: How to remove and install an oil pan on Four cylinder engine on Toyota Camry?A:Disconnect the cable from the negative battery terminal. Set the parking brake and block the rear wheels. Raise the front of the vehicle and support it securely on jackstands. Remove the two plastic splash shields under the engine, if equipped. Drain the engine oil and remove the oil filter. Remove the oil dipstick. Remove the bolts and detach the oil pan. If it's stuck, pry it loose very carefully with a small screwdriver or putty knife. Don't damage the mating surfaces of the pan and block them, or oil leaks could develop. Use a scraper to remove all traces of old sealant from the block and oil pan. Clean the mating surfaces with brake system cleaner. Make sure the threaded bolt holes in the block are clean. Check the oil pan flange for distortion, particularly around the bolt holes. Remove any nicks or burrs as necessary. Inspect the oil pump pick-up tube thoroughly for cracks and a blocked strainer. If the pickup was removed, clean it thoroughly and install it now, using a new gasket. Tighten the nuts and bolts to the torque. Apply a 3/16-inch-wide bead of RTV sealant to the mating surface of the oil pan. Carefully position the oil pan on the engine block and install the oil pan-to-engine block bolts loosely. Working from the center out, tighten the oil pan-to-engine block bolts to the torque in three or four steps. The remainder of installation is the reverse of removal. Be sure to wait at least one hour before adding oil to allow the sealant to properly cure. Run the engine and check for oil pressure and leaks.

- Q: How to remove the Oil Pan on V6 engine on Toyota Camry?A:The manufacturer recommends removing the engine and transaxle assembly to perform this procedure. To begin, drain the engine oil. Next, remove the bolts and nuts securing Oil Pan No. 2 to the larger cast aluminum oil pan. If it is stuck, tap it loose with a rubber-tipped mallet or carefully cut the sealant with a putty knife and hammer. Remove the oil pump pickup tube/strainer assembly and then the bolts and nuts securing oil pan No. 1 to the engine block. Carefully pry the oil pan loose from the engine block, being cautious to only pry in the designated areas. Remove the O-rings from the bottom of the engine block and, if necessary, the sheet metal baffle plate. For installation, first install the baffle plate if it was removed. Clean the mating surfaces of the block and oil pan and ensure the threaded holes in the block are clean. Install new O-rings on the block and check the flange of the steel oil pan for distortion. Flatten and restore the gasket surface if needed. Inspect and clean the strainer before installing it with a new gasket. Apply RTV sealant to the upper oil pan flange and position the pan onto the block, tightening the fasteners in several steps. Apply RTV sealant to the flange of the No. 2 oil pan, position it on the upper oil pan, and install the bolts. The remainder of the installation is the reverse of removal. Add oil, install a new filter, run the engine, and check for leaks.

Related Toyota Camry Parts

Browse by Year

2024 Oil Pan 2023 Oil Pan 2022 Oil Pan 2021 Oil Pan 2020 Oil Pan 2019 Oil Pan 2018 Oil Pan 2017 Oil Pan 2016 Oil Pan 2015 Oil Pan 2014 Oil Pan 2013 Oil Pan 2012 Oil Pan 2011 Oil Pan 2010 Oil Pan 2009 Oil Pan 2008 Oil Pan 2007 Oil Pan 2006 Oil Pan 2005 Oil Pan 2004 Oil Pan 2003 Oil Pan 2002 Oil Pan 2001 Oil Pan 2000 Oil Pan 1999 Oil Pan 1998 Oil Pan 1997 Oil Pan 1996 Oil Pan 1995 Oil Pan 1994 Oil Pan 1993 Oil Pan 1992 Oil Pan 1991 Oil Pan 1990 Oil Pan 1989 Oil Pan 1988 Oil Pan 1987 Oil Pan 1986 Oil Pan 1985 Oil Pan 1984 Oil Pan 1983 Oil Pan