×

- Live Chat

- 1-888-905-9199

My Garage

My Account

Cart

Genuine Toyota Highlander Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

199 Engine Mounts found

Toyota Highlander Rod, Engine Moving Control

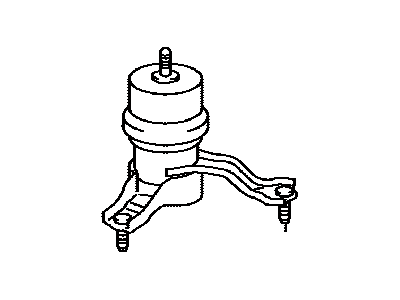

Part Number: 12363-0V010$87.31 MSRP: $123.07You Save: $35.76 (30%)Ships in 1-2 Business DaysToyota Highlander INSULATOR, Engine Mounting, LH

Part Number: 12372-28020$181.76 MSRP: $260.63You Save: $78.87 (31%)Ships in 1-3 Business DaysToyota Highlander INSULATOR, Engine Mounting, RH

Part Number: 12362-31040$170.46 MSRP: $242.33You Save: $71.87 (30%)Ships in 1-3 Business DaysToyota Highlander INSULATOR, Engine Mounting, LH

Part Number: 12372-20080$181.76 MSRP: $260.63You Save: $78.87 (31%)Ships in 1-3 Business DaysToyota Highlander INSULATOR, Engine Mounting, LH

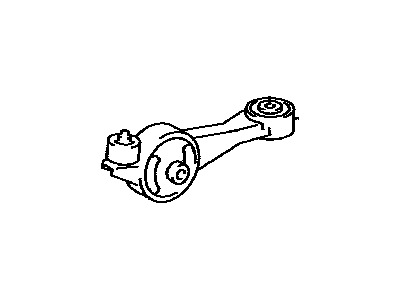

Part Number: 12372-28200$93.21 MSRP: $131.39You Save: $38.18 (30%)Ships in 1-3 Business DaysToyota Highlander Rod, Engine Moving Control

Part Number: 12363-31040$83.53 MSRP: $117.75You Save: $34.22 (30%)Ships in 1-2 Business DaysToyota Highlander Insulator, Engine Mounting, Rear

Part Number: 12371-20130$77.63 MSRP: $109.43You Save: $31.80 (30%)Ships in 1-3 Business DaysToyota Highlander INSULATOR, Engine Mounting, LH

Part Number: 12372-20060$181.76 MSRP: $260.63You Save: $78.87 (31%)Ships in 1-3 Business DaysToyota Highlander Rod, Engine Moving Control

Part Number: 12363-28120$68.07 MSRP: $95.96You Save: $27.89 (30%)Ships in 1-3 Business DaysToyota Highlander INSULATOR, Engine Mounting, RH

Part Number: 12362-28020$152.09 MSRP: $216.22You Save: $64.13 (30%)Ships in 1-3 Business DaysToyota Highlander Insulator, Engine Mounting, Front

Part Number: 12361-28100$90.02 MSRP: $126.90You Save: $36.88 (30%)Ships in 1-3 Business DaysToyota Highlander Insulator Assy, Engine Mounting, Front

Part Number: 12360-20080$191.39 MSRP: $274.44You Save: $83.05 (31%)Ships in 1-3 Business DaysToyota Highlander Rod, Engine Moving Control

Part Number: 12363-20111$88.25 MSRP: $124.40You Save: $36.15 (30%)Ships in 1-3 Business DaysToyota Highlander Rod, Engine Moving Control

Part Number: 12363-0P090$78.69 MSRP: $110.93You Save: $32.24 (30%)Ships in 1-2 Business DaysToyota Highlander Rod, Engine Moving Control

Part Number: 12363-0P210$75.86 MSRP: $106.94You Save: $31.08 (30%)Ships in 1-2 Business DaysToyota Highlander Rod, Engine Moving Control

Part Number: 12363-0P130$77.75 MSRP: $109.60You Save: $31.85 (30%)Ships in 1-3 Business DaysToyota Highlander INSULATOR, Engine Mounting

Part Number: 12362-0V040$154.66 MSRP: $219.88You Save: $65.22 (30%)Ships in 1-2 Business DaysToyota Highlander Bracket Sub-Assembly, En

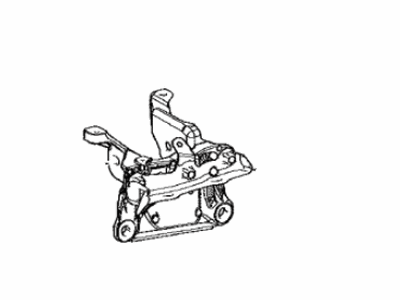

Part Number: 12304-F0010$177.53 MSRP: $254.56You Save: $77.03 (31%)Ships in 1-2 Business DaysToyota Highlander INSULATOR, Engine Mounting

Part Number: 12362-0P051$148.93 MSRP: $211.73You Save: $62.80 (30%)Toyota Highlander INSULATOR, Engine Mounting, RH

Part Number: 12362-0P040$161.30 MSRP: $229.31You Save: $68.01 (30%)

| Page 1 of 10 |Next >

1-20 of 199 Results

Toyota Highlander Engine Mount

If you are in demand for superior quality and affordable OEM Toyota Highlander Engine Mount, then shop with us! We own a wide range of the reduced-priced genuine Toyota Highlander Engine Mount. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Highlander Engine Mount Parts Questions & Experts Answers

- Q: How do you check and replace Engine Mounts in Four cylinder engine on Toyota Highlander?A: Engine Mounts seldom require attention, but broken or deteriorated mounts should be replaced immediately to prevent damage or wear on driveline components. During the check, the engine or transaxle must be raised slightly to remove the weight from the mounts. Raise the vehicle and support it securely on jackstands, then remove the splash shields under the engine and position a jack under the engine Oil Pan, using a large block of wood between the jack and the oil pan to carefully raise the engine just enough to take the weight off the mounts, avoiding positioning the wood block under the oil drain plug. Inspect the mounts for cracked, hardened rubber or separation from the bushing in the center, and check for relative movement between the mount plates and the engine or frame, using a large screwdriver or pry bar to attempt to move the mounts; if movement is noted, lower the engine and tighten the mount fasteners. Apply rubber preservative to the mounts to slow deterioration. Disconnect the cable from the negative battery terminal, then raise the vehicle and support it securely on jackstands if not already done, and support the engine. If several mounts need replacement, only replace one at a time and tighten them as you go. For the passenger's side engine mount, remove the nuts securing the mount to the upper and lower brackets, then remove the bolts securing the mount to the frame and raise the transaxle enough to allow removal of the mount, ensuring to loosen the mounting nuts on the other engine mounts at the subframe for clearance. Installation is the reverse of removal, using thread-locking compound on the bolts and tightening them securely. For the driver's side transaxle mount, remove the nut securing the mount to the upper and lower brackets, then remove the bolts securing the mount to the frame and raise the engine enough for removal, again ensuring to loosen the mounting nuts on the other engine mounts for clearance. Installation follows the same reverse process with thread-locking compound. For the front engine mount, remove the fastener securing the mount to the bracket, then remove the bolts securing the mount to the frame and raise the engine enough for removal, with installation being the reverse and using thread-locking compound. For the rear engine mount, remove the mount nut and slide the through bolt out of the insulator, then remove the bolts securing the mount to the frame and raise the engine enough for removal, with installation being the reverse and using thread-locking compound. Finally, in the engine compartment, remove the bolts securing the engine movement control rod and its bracket, with installation being the reverse and using thread-locking compound on the bolts.

Related Toyota Highlander Parts

Browse by Year

2024 Engine Mount 2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2014 Engine Mount 2013 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount 2005 Engine Mount 2004 Engine Mount 2003 Engine Mount 2002 Engine Mount 2001 Engine Mount