My Garage

My Account

Cart

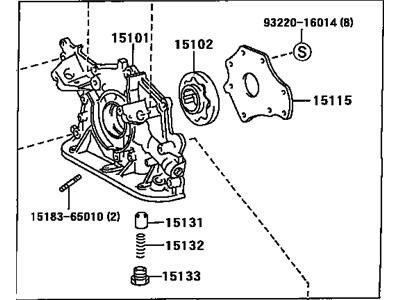

Genuine Toyota Land Cruiser Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Oil Pumps found

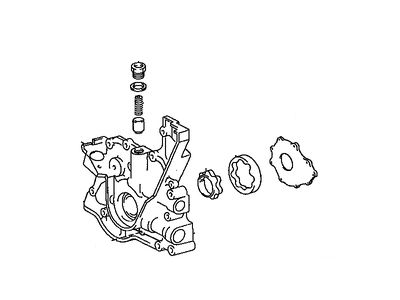

Toyota Land Cruiser Rotor Set, Oil Pump

Part Number: 15102-66020$36.52 MSRP: $51.05You Save: $14.53 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Rotor Set, Oil Pump

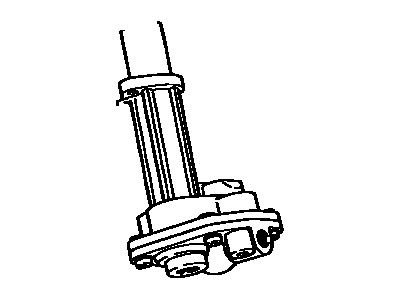

Part Number: 15103-38060$60.05 MSRP: $84.65You Save: $24.60 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Oil Pump Assembly

Part Number: 15100-50050$329.20 MSRP: $472.05You Save: $142.85 (31%)Ships in 1-3 Business DaysToyota Land Cruiser Rotor Set, Oil Pump

Part Number: 15103-0S010$60.05 MSRP: $84.65You Save: $24.60 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Oil Pump Assembly

Part Number: 15100-61011$268.18 MSRP: $384.55You Save: $116.37 (31%)Ships in 1-3 Business DaysToyota Land Cruiser Oil Pump Assembly

Part Number: 15100-61010$268.18 MSRP: $384.55You Save: $116.37 (31%)Ships in 1-3 Business DaysToyota Land Cruiser Oil Pump Assembly

Part Number: 15100-50040$358.13 MSRP: $534.25You Save: $176.12 (33%)Ships in 1-3 Business DaysToyota Land Cruiser Oil Pump Assembly

Part Number: 15100-61020$296.48 MSRP: $425.14You Save: $128.66 (31%)Ships in 1-3 Business DaysToyota Land Cruiser Oil Pump Assembly

Part Number: 15100-60014$268.18 MSRP: $384.55You Save: $116.37 (31%)Ships in 1-3 Business Days

Toyota Land Cruiser Oil Pump

If you are in demand for superior quality and affordable OEM Toyota Land Cruiser Oil Pump, then shop with us! We own a wide range of the reduced-priced genuine Toyota Land Cruiser Oil Pump. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Land Cruiser Oil Pump Parts Questions & Experts Answers

- Q: How to remove and install oil pump in Pushrod engine on Toyota Land Cruiser?A:The oil pump is highly sensitive and thus calling for its replacement every time the oil pan is removed is highly recommendable. If there is an idea that the oil pressure is low, then it is mandatory to inspect the oil pressure before following the removal of the oil pan. The initial steps involve the prior elimination of the oil pan; next, two attaching bolts of the oil pump from the block should be removed; finally, it is possible to separate the oil pump and strainer assembly from the block. If the pump is bad, remove it out of the engine and get a new one, in the course of doing an overhaul on the engine, do not scrap the original and try to rebuild the oil pump . To install, rotate the shaft in a manner that has tang of the gear fits into the slot at the lower end of distributor drive and that has the oil pump drive fits into the protruding part of the distributor drive gear. The oil pump should go into that slot rather smoothly; if it does not, the tang needs to be adjusted to create a better fit. Subsequently, fit the pump attaching bolts, and thereafter, tighten them to the torque value suggested. Last but not the least, re-attach the oil pan and pour some oil and on starting the engine ensure that there is no leakage of oil.

Related Toyota Land Cruiser Parts

Browse by Year

2021 Oil Pump 2020 Oil Pump 2019 Oil Pump 2018 Oil Pump 2017 Oil Pump 2016 Oil Pump 2015 Oil Pump 2014 Oil Pump 2013 Oil Pump 2012 Oil Pump 2011 Oil Pump 2010 Oil Pump 2009 Oil Pump 2008 Oil Pump 2007 Oil Pump 2006 Oil Pump 2005 Oil Pump 2004 Oil Pump 2003 Oil Pump 2002 Oil Pump 2001 Oil Pump 2000 Oil Pump 1999 Oil Pump 1998 Oil Pump 1997 Oil Pump 1996 Oil Pump 1995 Oil Pump 1994 Oil Pump 1993 Oil Pump 1992 Oil Pump 1991 Oil Pump 1990 Oil Pump 1989 Oil Pump 1988 Oil Pump 1987 Oil Pump 1986 Oil Pump 1985 Oil Pump 1984 Oil Pump 1983 Oil Pump 1982 Oil Pump 1981 Oil Pump 1980 Oil Pump 1979 Oil Pump 1978 Oil Pump 1977 Oil Pump 1976 Oil Pump 1975 Oil Pump 1974 Oil Pump 1973 Oil Pump 1972 Oil Pump 1971 Oil Pump 1970 Oil Pump 1969 Oil Pump