My Garage

My Account

Cart

Genuine Toyota Land Cruiser Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

43 Rod Bearings found

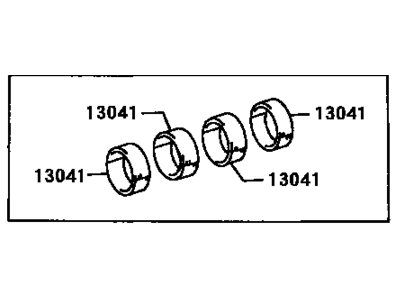

Toyota Land Cruiser Bearing Set, Connecting Rod

Part Number: 13204-66020$124.00 MSRP: $176.29You Save: $52.29 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-38060-02$12.17 MSRP: $17.02You Save: $4.85 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing Set, Connecting Rod

Part Number: 13204-60011$108.25 MSRP: $152.60You Save: $44.35 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing Set, Connecting Rod

Part Number: 13202-60011$86.38 MSRP: $121.75You Save: $35.37 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-35020-B0$12.80 MSRP: $17.90You Save: $5.10 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-35020-A0$12.26 MSRP: $17.13You Save: $4.87 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-50031-04$16.46 MSRP: $23.00You Save: $6.54 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-38060-04$12.84 MSRP: $17.95You Save: $5.11 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-38060-06$11.65 MSRP: $16.28You Save: $4.63 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-38060-05$12.17 MSRP: $17.02You Save: $4.85 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-38060-07$11.65 MSRP: $16.28You Save: $4.63 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-50030-03$16.46 MSRP: $23.00You Save: $6.54 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-50030-04$16.46 MSRP: $23.00You Save: $6.54 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing Set, Connecting Rod

Part Number: 13204-61020$103.97 MSRP: $146.56You Save: $42.59 (30%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-38060-03$12.17 MSRP: $17.02You Save: $4.85 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-50030-02$16.46 MSRP: $23.00You Save: $6.54 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-50031-02$16.46 MSRP: $23.00You Save: $6.54 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-35020-0A$12.26 MSRP: $17.13You Save: $4.87 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing, Connecting Rod

Part Number: 13041-66020-06$17.97 MSRP: $25.12You Save: $7.15 (29%)Ships in 1-3 Business DaysToyota Land Cruiser Bearing Set, Connecting Rod

Part Number: 13206-60011$99.72 MSRP: $140.57You Save: $40.85 (30%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 43 Results

Toyota Land Cruiser Rod Bearing

If you are in demand for superior quality and affordable OEM Toyota Land Cruiser Rod Bearing, then shop with us! We own a wide range of the reduced-priced genuine Toyota Land Cruiser Rod Bearing. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

Toyota Land Cruiser Rod Bearing Parts Questions & Experts Answers

- Q: What are the essential procedures and considerations for replacing and inspecting main and connecting rod bearings during an engine overhaul on Toyota Land Cruiser?A: When overhauling an engine, a smart move is to change the main and connecting rod bearings, keep the old ones so as to study them, these offer clues to the overall performance of the engine. This mostly originates from lack of lubrication, contaminants such as dirt or any foreign particle, overloading of the engine, or corrosion, and such issues must be fixed prior to the next assembly. When inspecting bearings, pull them out of their corresponding locations and arrange them neatly for possible pairing of the defects with the crankshaft journal. Foreign particles could be forced into the engine during the assembling process, getting through the filters, or through the machining of Bear inGs; and small foreign bodies tend to get lodged into the bearing material, larger bodies, on the other hand, result in scoring. Precautions include frequent washing of all the components and regular changing of oil and filter. Thus, the cases of failure in lubrication may be caused by issues like overheating, overloading, oil leaks or blockage of the oil circulation channels which results to severe damages. Other driving conditions, like full throttle at low speeds or short distances, also affects bearing life as well by wearing off the oil film and also leading to corrosion. A proper assembly is not achieved, for example tight fitting bearings or trapped dirt, results in the cutting off of oil supply and thus fails. When it comes to bearings, in case of clearance or supply of wrong bearings or replacement of original bearings, refer the chart to select the standard bearings. If the crankshaft has been reground, new undersize bearings will be required and the automotive machine shop can help in choosing the correct one. The oil clearance obtained ought to be used to determine the right size bearings, by referring to the record of Plastigage. In factory-assembled engines, bearings utilize different coloured insert and the journal size codes are normally inscribed on the crankshaft. If achieving select fit is required it is possible to have two inserts of different sizes one being larger than the other; however, one must ensure that these sizes do not differ by more than 0.001 inch. Generally, odd-size inserts must be complementary, with all top inserts the same size and all bottom ones the same size.

Related Toyota Land Cruiser Parts

Browse by Year

2021 Rod Bearing 2020 Rod Bearing 2019 Rod Bearing 2018 Rod Bearing 2017 Rod Bearing 2016 Rod Bearing 2015 Rod Bearing 2014 Rod Bearing 2013 Rod Bearing 2012 Rod Bearing 2011 Rod Bearing 2010 Rod Bearing 2009 Rod Bearing 2008 Rod Bearing 2007 Rod Bearing 2006 Rod Bearing 2005 Rod Bearing 2004 Rod Bearing 2003 Rod Bearing 2002 Rod Bearing 2001 Rod Bearing 2000 Rod Bearing 1999 Rod Bearing 1998 Rod Bearing 1997 Rod Bearing 1996 Rod Bearing 1995 Rod Bearing 1994 Rod Bearing 1993 Rod Bearing 1992 Rod Bearing 1991 Rod Bearing 1990 Rod Bearing 1989 Rod Bearing 1988 Rod Bearing 1987 Rod Bearing 1986 Rod Bearing 1985 Rod Bearing 1984 Rod Bearing 1983 Rod Bearing 1982 Rod Bearing 1981 Rod Bearing 1980 Rod Bearing 1979 Rod Bearing 1978 Rod Bearing 1977 Rod Bearing 1976 Rod Bearing 1975 Rod Bearing 1974 Rod Bearing 1973 Rod Bearing 1972 Rod Bearing 1971 Rod Bearing 1970 Rod Bearing 1969 Rod Bearing