My Garage

My Account

Cart

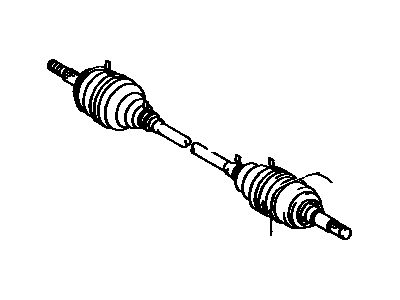

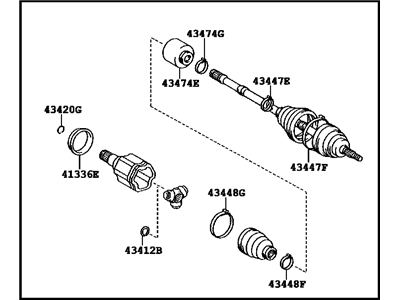

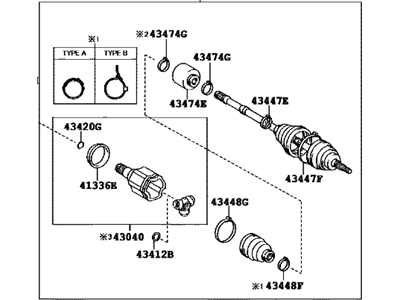

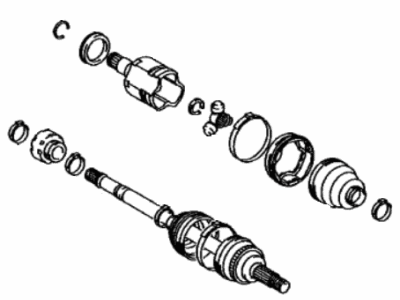

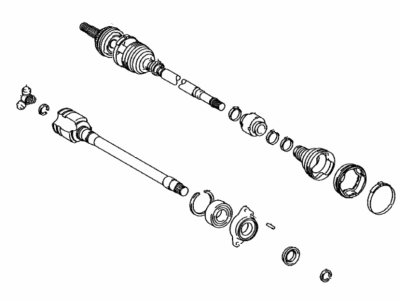

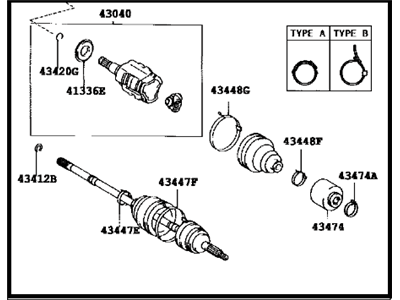

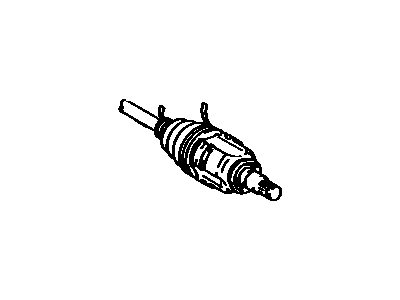

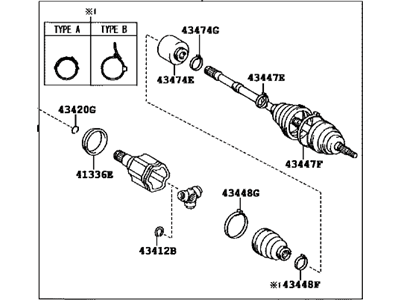

Genuine Toyota RAV4 Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

215 Axle Shafts found

Toyota RAV4 Front Drive Shaft Assembly

Part Number: 43410-0R092$428.48 MSRP: $639.21You Save: $210.73 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly

Part Number: 43420-06B30$391.02 MSRP: $583.33You Save: $192.31 (33%)Ships in 1-2 Business DaysToyota RAV4 Front Drive Shaft Assembly Left Hand

Part Number: 43420-0R080$346.20 MSRP: $516.46You Save: $170.26 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly

Part Number: 43420-33330$392.80 MSRP: $585.98You Save: $193.18 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly Left Hand

Part Number: 43420-0R010$297.38 MSRP: $452.96You Save: $155.58 (35%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly Right Hand

Part Number: 43410-0R030$366.94 MSRP: $573.92You Save: $206.98 (37%)Toyota RAV4 Front Drive Shaft Assembly

Part Number: 43420-0R082$346.20 MSRP: $516.46You Save: $170.26 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly Left Hand

Part Number: 43420-0R081$346.20 MSRP: $516.46You Save: $170.26 (33%)Ships in 1-2 Business DaysToyota RAV4 Front Drive Shaft Assembly Right Hand

Part Number: 43410-0R091$428.48 MSRP: $639.21You Save: $210.73 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly

Part Number: 43410-42201$413.43 MSRP: $616.76You Save: $203.33 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly

Part Number: 43420-28091$391.69 MSRP: $584.32You Save: $192.63 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly Right Hand

Part Number: 43410-0R090$428.48 MSRP: $639.21You Save: $210.73 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly

Part Number: 43420-33340$610.02 MSRP: $910.84You Save: $300.82 (34%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly

Part Number: 43420-42191$391.69 MSRP: $584.32You Save: $192.63 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly Right Hand

Part Number: 43410-0R040$451.23 MSRP: $673.14You Save: $221.91 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly

Part Number: 43410-06A80$411.65 MSRP: $614.09You Save: $202.44 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly Left Hand

Part Number: 43420-42120$412.32 MSRP: $615.09You Save: $202.77 (33%)Ships in 1-3 Business DaysToyota RAV4 Shaft Assembly, Rear Drive, Right

Part Number: 42330-42050$374.18 MSRP: $558.21You Save: $184.03 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly Right Hand

Part Number: 43410-42200$413.43 MSRP: $616.76You Save: $203.33 (33%)Ships in 1-3 Business DaysToyota RAV4 Front Drive Shaft Assembly Left Hand

Part Number: 43420-42160$358.80 MSRP: $535.25You Save: $176.45 (33%)Ships in 1-3 Business Days

| Page 1 of 11 |Next >

1-20 of 215 Results

Toyota RAV4 Axle Shaft

If you are in demand for superior quality and affordable OEM Toyota RAV4 Axle Shaft, then shop with us! We own a wide range of the reduced-priced genuine Toyota RAV4 Axle Shaft. You can purchase in confidence as all parts come with a manufacturer's warranty. Any issues with our products? No need to worry as we have a hassle-free return policy to guide you every step of the way.

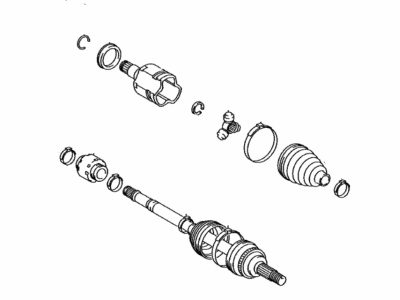

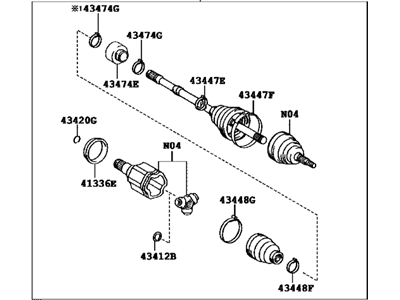

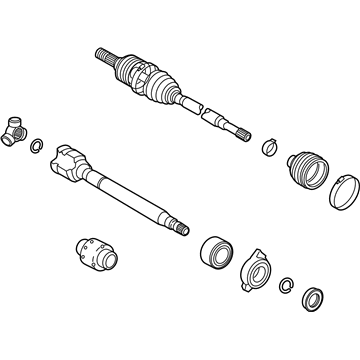

Toyota RAV4 Axle Shaft Parts Questions & Experts Answers

- Q: How to remove and install the front axle shaft on a Toyota Rav4?A:To disassemble the car's axle shaft, you need to start by unscrewing the wheel cover or hub cap, and then using a punch or chisel to loosen the nut. Loosen the nut on the axle shaft/hub by using a socket and a Large Breaker Bar and in case the wheel design restricts this, move to the next process. Uncentre the wheel studs, support the car adequately by jackstands, and take out the wheel. If needed, start making a punch into the cooling vanes of the brake disc so that the hub would not rotate and you can loosen the nut. To do this, throw in the engine undercovers, pull the ABS speed sensor connector and, finally, pull off the axle shaft/hub nut while noting the position of the axle to the hub for reconstruction purposes. Unfasten the stabilizer bar link, then remove the ball joint nuts and bolt; finally, disengage the lower control arm from the ball joint. They indicate that if they are reinstallation of the same axle and hub then their relationship should be marked. Swing the knuckle/hub assembly out until the axle shaft is free, resting the outer end on an intermediate support to keep irregular stress on the inside CV joint. For the passenger's side, you have to first take out the snap-ring on the bearing bracket and the bolt that goes along with it, followed by pulling out the axle shaft. For the driver's side, one must first remove the inner CV joint from the transaxle through the use of the slide hammer. As earlier pointed, during the installation they have to remove the old spring clip at the inner end of the axle shaft, lubricate the differential seal and later lift the actual axle shaft into position. Push the inner CV joint splines into the differential side gear; the spring clip should engage when it is done so. For the passenger's side, fit a new bearing support snap ring and torque the centre support bearing bolt to the required specification. After that, grease the outer CV joint splines, place the stub axle to the hub and tighten the nut for the ball joint to the lower/upper control arm. Place a new axle shaft/hub nut on the spindle and snug preferably to the standard nut torque value but not beyond before lowering the vehicle. Make sure the axle shaft is closed firmly onto the transaxle, then fit the wheel and torque the lug nuts to the specified value, lower the car and torque all the bolts correctly. For AWD models, the same techniques should be used for this procedure and the ABS speed sensor, as well as the rear differential support braces must be disconnected where applicable.

Related Toyota RAV4 Parts

Browse by Year

2024 Axle Shaft 2023 Axle Shaft 2022 Axle Shaft 2021 Axle Shaft 2020 Axle Shaft 2019 Axle Shaft 2018 Axle Shaft 2017 Axle Shaft 2016 Axle Shaft 2015 Axle Shaft 2014 Axle Shaft 2013 Axle Shaft 2012 Axle Shaft 2011 Axle Shaft 2010 Axle Shaft 2009 Axle Shaft 2008 Axle Shaft 2007 Axle Shaft 2006 Axle Shaft 2005 Axle Shaft 2004 Axle Shaft 2003 Axle Shaft 2002 Axle Shaft 2001 Axle Shaft 2000 Axle Shaft 1999 Axle Shaft 1998 Axle Shaft 1997 Axle Shaft 1996 Axle Shaft