My Garage

My Account

Cart

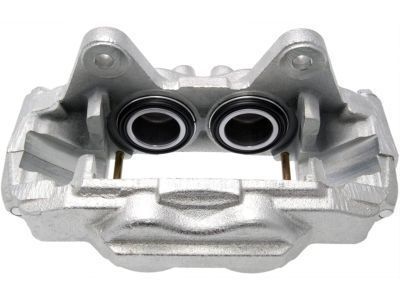

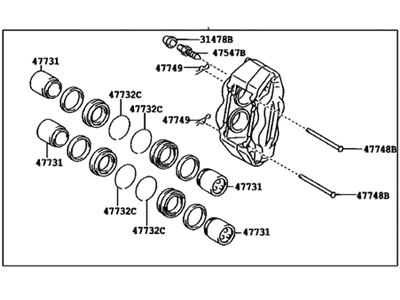

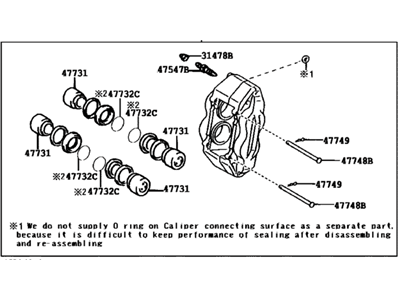

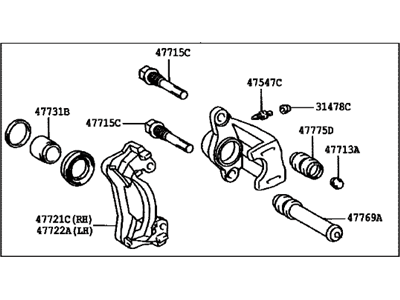

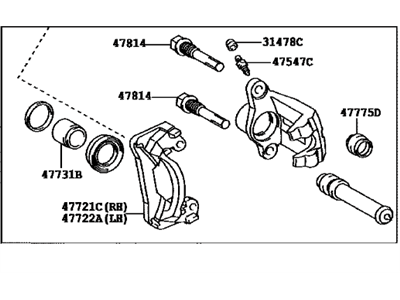

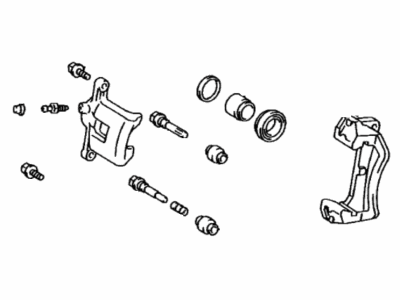

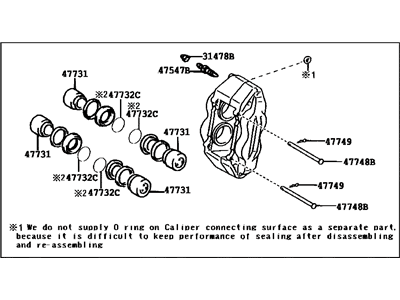

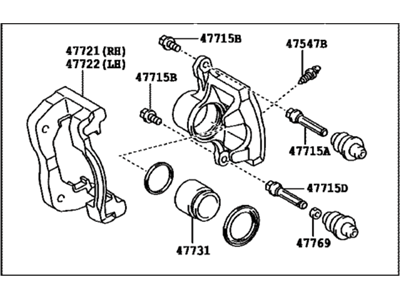

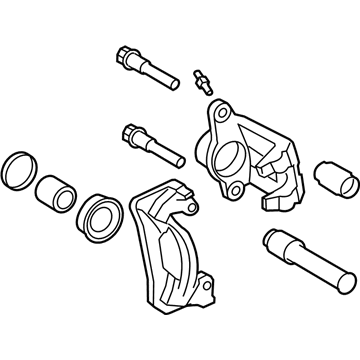

Genuine Toyota Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

591 Brake Calipers found

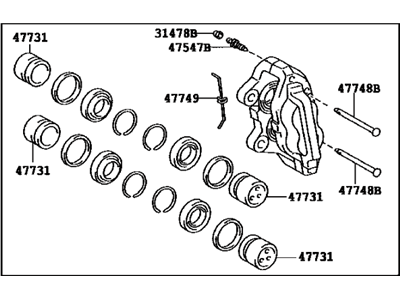

Toyota Disc Brake Cylinder Assembly

Part Number: 47730-60300$174.90 MSRP: $248.65You Save: $73.75 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Front Disc Brake, RH; Caliper

- Position: Passenger Side

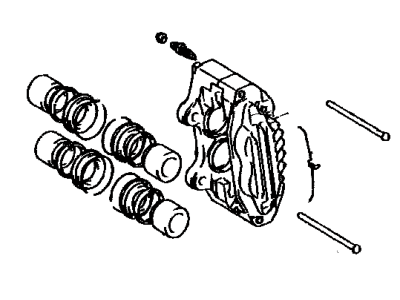

Toyota Disc Brake Cylinder Assembly

Part Number: 47750-60300$180.02 MSRP: $258.14You Save: $78.12 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, LH; Caliper

- Position: Driver Side

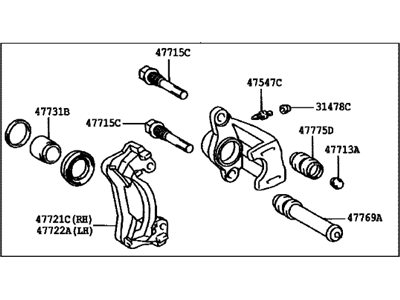

Toyota Disc Brake Cylinder Assembly Left Hand

Part Number: 47750-0C030$202.64 MSRP: $290.57You Save: $87.93 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, LH; Caliper

- Position: Driver Side

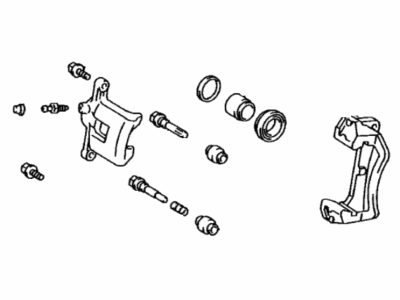

Toyota Front Disc Brake Cylinder Assembly Right Hand

Part Number: 47730-0C030$202.64 MSRP: $290.57You Save: $87.93 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Assy, Front Disc Brake, RH; Caliper

- Position: Passenger Side

Toyota Disc Brake Cylinder Assembly Left Hand

Part Number: 47750-60061$159.46 MSRP: $226.70You Save: $67.24 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, LH; Caliper

- Position: Driver Side

Toyota Front Disc Brake Cylinder Assembly Right Hand

Part Number: 47730-60061$191.39 MSRP: $274.44You Save: $83.05 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Front Disc Brake, RH; Caliper

- Position: Passenger Side

Toyota Disc Brake Cylinder Assembly Rear Left Hand

Part Number: 47750-34030$171.73 MSRP: $244.15You Save: $72.42 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, Rear LH; Caliper

- Position: Rear Driver Side

Toyota Rear Disc Brake Cylinder Assembly Right Hand

Part Number: 47730-60101$175.49 MSRP: $249.49You Save: $74.00 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Assy, Rear Disc Brake, RH; Caliper

- Position: Passenger Side

- Replaces: 47730-60100

Toyota Disc Brake Cylinder Assembly Left Hand

Part Number: 47750-04092$194.52 MSRP: $278.93You Save: $84.41 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, LH; Caliper

- Position: Driver Side

- Replaces: 47750-04090, 47750-04091

Toyota Front Disc Brake Cylinder Assembly Right Hand

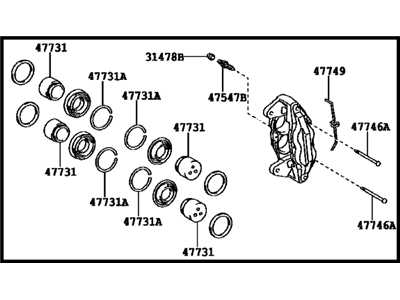

Part Number: 47730-35411$219.46 MSRP: $314.69You Save: $95.23 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Assy, Front Disc Brake, RH; Caliper

- Manufacturer Note: FRONT WHEEL BRAKE-16 IN

- Position: Passenger Side

- Replaces: 47730-35160

Toyota Disc Brake Cylinder Assembly Left Hand

Part Number: 47750-35411$219.46 MSRP: $314.69You Save: $95.23 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, LH; Caliper

- Manufacturer Note: FRONT WHEEL BRAKE-16 IN

- Position: Driver Side

- Replaces: 47750-35160

Toyota Rear Disc Brake Cylinder Assembly Right Hand

Part Number: 47730-34030$163.44 MSRP: $232.36You Save: $68.92 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Rear Disc Brake, RH; Caliper

- Position: Passenger Side

Toyota Disc Brake Cylinder Assembly

Part Number: 47750-60350$142.96 MSRP: $203.25You Save: $60.29 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, LH; Caliper

- Position: Driver Side

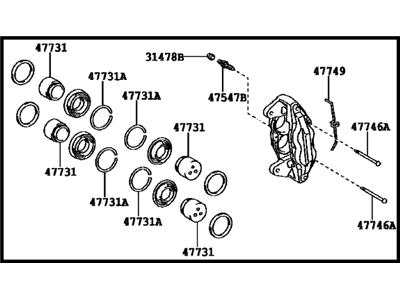

Toyota Disc Brake Cylinder Assembly Left Hand

Part Number: 47750-60261$248.23 MSRP: $355.94You Save: $107.71 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, LH; Caliper

- Manufacturer Note: FRONT WHEEL BRAKE-17 INCHES

- Position: Driver Side

- Replaces: 47750-60130

Toyota Disc Brake Cylinder Assembly

Part Number: 47730-60350$142.96 MSRP: $203.25You Save: $60.29 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Front Disc Brake, RH; Caliper

- Position: Passenger Side

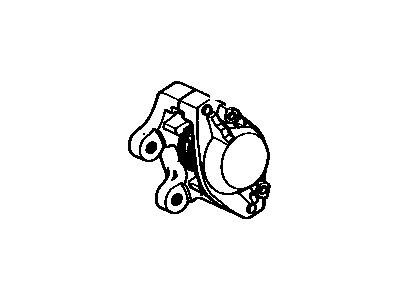

Toyota Rear Disc Brake Cylinder Assembly Right Hand

Part Number: 47830-0C010$120.62 MSRP: $171.48You Save: $50.86 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Rear Disc Brake, RH; Caliper

- Position: Passenger Side

Toyota Disc Brake Cylinder Assembly Rear Left Hand

Part Number: 47750-60101$175.49 MSRP: $249.49You Save: $74.00 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, Rear LH; Caliper

- Position: Rear Driver Side

- Replaces: 47750-60100

Toyota Front Disc Brake Cylinder Assembly Right Hand

Part Number: 47730-60261$254.84 MSRP: $365.43You Save: $110.59 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Front Disc Brake, RH; Caliper

- Manufacturer Note: FRONT WHEEL BRAKE-17 INCHES

- Position: Passenger Side

- Replaces: 47730-60130

Toyota Front Disc Brake Cylinder Assembly Right Hand

Part Number: 47730-04092$196.49 MSRP: $281.76You Save: $85.27 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cylinder Assy, Front Disc Brake, RH; Caliper

- Position: Passenger Side

- Replaces: 47730-04091, 47730-04090

Toyota Disc Brake Cylinder Assembly Rear Left Hand

Part Number: 47850-0C010$120.62 MSRP: $171.48You Save: $50.86 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Cylinder Assy, Disc Brake, Rear LH; Caliper

- Position: Rear Driver Side

| Page 1 of 30 |Next >

1-20 of 591 Results

About Toyota Brake Caliper

Arguably the key component of your car's brake system, the Toyota brake caliper operates just like a small hydraulic clamp designed to grip the brake rotor and bring your car to a halt. The Toyota brake caliper has to be extremely strong to withstand the incredible forces generated as it tries to drag two tons of car to a halt. Abnormal braking-the car pulling to one side or the other-is another good sign that there's something amiss in the Toyota brake caliper. If you've ever seen or worked on a Toyota brake caliper, you know what we're talking about.

Toyota Brake Caliper Parts Questions & Experts Answers

- Q: Should Brake Calipers Always Be Replaced in Pairs on 2003-2009 Toyota 4Runner?A:When using the calipers, to avoid the chances of getting different measurements it is recommended that they be returned in pairs. First, remove the front wheel lug nuts, then lift the front of the vehicle off the ground and set it on jack stands, engage the parking brake. Take off the wheels and relocate the draining pan underneath the brake assembly, using brake system cleaner to clean up the caliper and area. As for a fixed type front caliper, if replacement is required, then you have to take off the brake pads; but if not, simply slide the brake pads to the side of the caliper to obtain space for clearance. Lift the outboard brake pad, push both pistons into their bores with a brake piston brush, clean the contact surfaces, smears the back of the new brake pad with high temp grease, and install an anti squeal shim. Using a flare nut wrench, remove the brake line from the caliper; keep all the opening covered to avoid the loss of brake fluid and do this very carefully without spilling the brake fluid. Take off the caliper mounting bolts to release and raise the caliper off the knuckle. If on the floating type of rear caliper remove the brake hose banjo bolt and cap the hose to avoid seepage of the oil. Slide or unbolt the mounting bolts of the caliper, then pull up the caliper or off the bracket until the clips on the rubber boot can be lifted in an upward motion; if still connected to the hose, then support with wire. The process of installation again involves reverse of removal and it is followed by tightening the caliper mounting bolts to the required torque. While mounting front calipers, put the brake line and tighten it and for the rear calipers new sealing washer must be placed and tighten the banjo bolt. Finally check the operation of the brakes, bleed the brake system and then replace the wheels and the lug nuts, lower the wheel, tighten the lug nuts ad finally you return the vehicle to normal service.

Related Toyota Parts

Browse by Model

4Runner Brake Caliper 86 Brake Caliper Avalon Brake Caliper C-HR Brake Caliper Camry Brake Caliper Celica Brake Caliper Corolla Brake Caliper Corolla Cross Brake Caliper Corolla iM Brake Caliper Corona Brake Caliper Cressida Brake Caliper Crown Brake Caliper Echo Brake Caliper FJ Cruiser Brake Caliper GR Corolla Brake Caliper GR Supra Brake Caliper GR86 Brake Caliper Grand Highlander Brake Caliper Highlander Brake Caliper Land Cruiser Brake Caliper MR2 Brake Caliper MR2 Spyder Brake Caliper Matrix Brake Caliper Mirai Brake Caliper Paseo Brake Caliper Pickup Brake Caliper Previa Brake Caliper Prius AWD-e Brake Caliper Prius Brake Caliper Prius C Brake Caliper Prius Prime Brake Caliper Prius V Brake Caliper RAV4 Brake Caliper RAV4 Prime Brake Caliper Sequoia Brake Caliper Sienna Brake Caliper Solara Brake Caliper Starlet Brake Caliper Supra Brake Caliper T100 Brake Caliper Tacoma Brake Caliper Tercel Brake Caliper Tundra Brake Caliper Van Brake Caliper Venza Brake Caliper Yaris Brake Caliper Yaris iA Brake Caliper bZ4X Brake Caliper